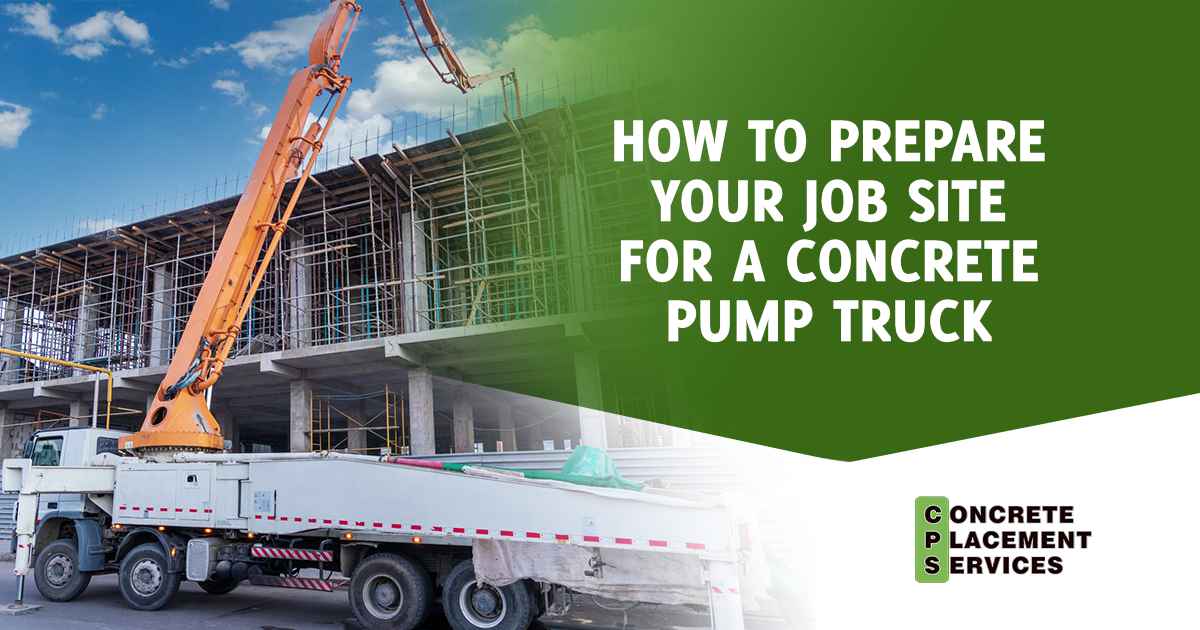

Contractors preparing for an upcoming concrete pour must understand the key requirements before scheduling a concrete pump. Proper planning ensures the operation is safe, efficient, and stays on schedule. Site access, equipment setup, timing with ready-mix deliveries, and communication with the pumping crew all affect the flow of the pour. When contractors review these factors ahead of time, they reduce delays, maintain safety, and allow the pumping provider to perform the job effectively. Early preparation and reliable communication make the pour predictable and smooth.

Site Access Requirements Before Scheduling a Concrete Pump

Site access is one of the most critical factors contractors must confirm before scheduling a concrete pumping company. Pump trucks are heavy, large vehicles that need stable, unobstructed paths to reach the setup area. Without proper access, the truck may be unable to position itself safely, causing delays and potential safety risks. Reviewing access points in advance helps the operator maneuver efficiently and keeps the pour on schedule.

Key Site Access Considerations

- Ground stability: Ensure the soil or pavement can support the weight of the pump truck.

- Clear path: Remove trees, parked vehicles, construction debris, and low-hanging obstacles.

- Sufficient space: Confirm there is room for safe entry, turning, positioning, and outrigger deployment.

Contractors should assess the route from the street to the pour area and identify any tight turns or obstacles. Limited space may require notifying the pumping provider so the correct truck can be dispatched. Ground reinforcement or support pads may be necessary in areas with soft or uneven terrain to stabilize the outriggers. Proper access planning sets the foundation for safe and efficient pumping operations.

Additional site preparation includes:

- Keeping emergency access routes open during the pour.

- Marking underground utilities that could be affected by the truck setup.

- Coordinating with other trades to ensure walkways and drive lanes remain clear.

Timing and Scheduling Considerations for Concrete Pumping Services

Timing is essential for a smooth concrete pumping operation. The schedule involves coordination between the pump operator, ready-mix supplier, and the contractor’s onsite crew. Any disruption in timing can slow the pour or cause downtime. Planning the pour schedule in advance helps avoid unnecessary delays and ensures continuous concrete placement.

Pour Time Selection

Early morning pours are preferred to reduce traffic delays and take advantage of cooler temperatures. Contractors must ensure that the setup area is ready before the pump truck arrives. This includes clearing the site, confirming access, and coordinating with other trades to avoid conflicts.

Coordination With Ready-Mix Trucks

The pump operator cannot start until the first ready-mix truck arrives. A steady flow of concrete trucks is necessary to maintain continuous pumping. Delays in delivery may require cleaning and resetting the pump, adding labor time and slowing the pour. Clear communication between the contractor, ready-mix supplier, and pumping provider minimizes this risk.

Pump Setup Time

Pump trucks require space to deploy outriggers, position the boom or hose, and complete safety checks. Contractors must allow sufficient setup time to prevent rushed operations. Planning setup time ensures the operator can start pumping safely and efficiently.

Coordination With Concrete Pumping Equipment and Crew

Coordination between the contractor and the pumping crew is critical for an efficient and safe pour. Pump operators need accurate information about the pour area, required reach, and concrete volume. Miscommunication can result in improper equipment positioning and workflow disruptions.

Pour Plan Review

Contractors should review the pour plan with the operator before pumping begins. This includes identifying the pour location, confirming the hose or boom path, and noting any obstacles. Providing drawings or layouts in advance ensures the operator selects and positions the proper equipment.

Safe Work Zone

A controlled work area is necessary around the pump truck. Pumping involves high-pressure hoses and moving boom sections, so only trained personnel should be in the active zone. Removing unnecessary workers improves safety and allows the operator to focus on equipment control.

Crew Support

Contractors must provide labor for hose handling and concrete placement. Proper coordination ensures the crew is prepared to manage concrete as it arrives, improving efficiency and reducing the risk of mistakes.

Space Planning and Setup Needs for Concrete Pump Trucks

Pump trucks require a stable, open area for safe operation. Contractors should plan the setup zone to accommodate the truck size, outriggers, and hose or boom movement. Proper setup prevents delays and ensures safety for both operators and crew.

Outrigger Placement

Outriggers stabilize the truck and must extend fully on level ground. Contractors should inspect the area for uneven or soft terrain and provide reinforcement if needed.

Hose or Boom Routing

Contractors must plan a clear path for the hose or boom to prevent obstructions, tripping hazards, and interference with overhead power lines. A clear routing plan ensures efficient concrete placement.

Maintaining Access During the Pour

Once the pump truck is positioned, it cannot be moved until the pour is complete. Contractors must keep the area free from vehicles, equipment, and other trades to allow uninterrupted operation.

Communication Expectations When Working With a Concrete Pumping Company

Clear communication with the pumping provider ensures an efficient, safe, and predictable pour. Contractors must provide detailed information about the project, including concrete volume, mix type, hose length, and pour location. Accurate details help the operator select the proper equipment and plan the setup.

Ongoing communication is crucial if schedules change, access points shift, or the pour area is modified. Timely updates allow the operator to adjust the plan and avoid delays. Experienced pumping providers help guide contractors through proper planning and scheduling, improving overall efficiency.

Why Early Planning Matters Before Scheduling a Concrete Pump

Early planning reduces risks and supports efficient operations. Concrete pumping involves heavy equipment, pressurized systems, and strict timing. Reviewing access points, scheduling deliveries, coordinating with the crew, and maintaining clear communication prevents downtime and ensures smooth placement.

Working with skilled operators amplifies these benefits. Contractors can rely on experienced professionals, like those featured on the company’s Concrete Pumping Services page, to manage logistics and maintain safety throughout the pour.

Ready to Schedule a Concrete Pumping Service?

Call 843-247-1489 or fill out the contact form now to secure experienced operators and reliable equipment for a safe, efficient, and on-schedule concrete pour.